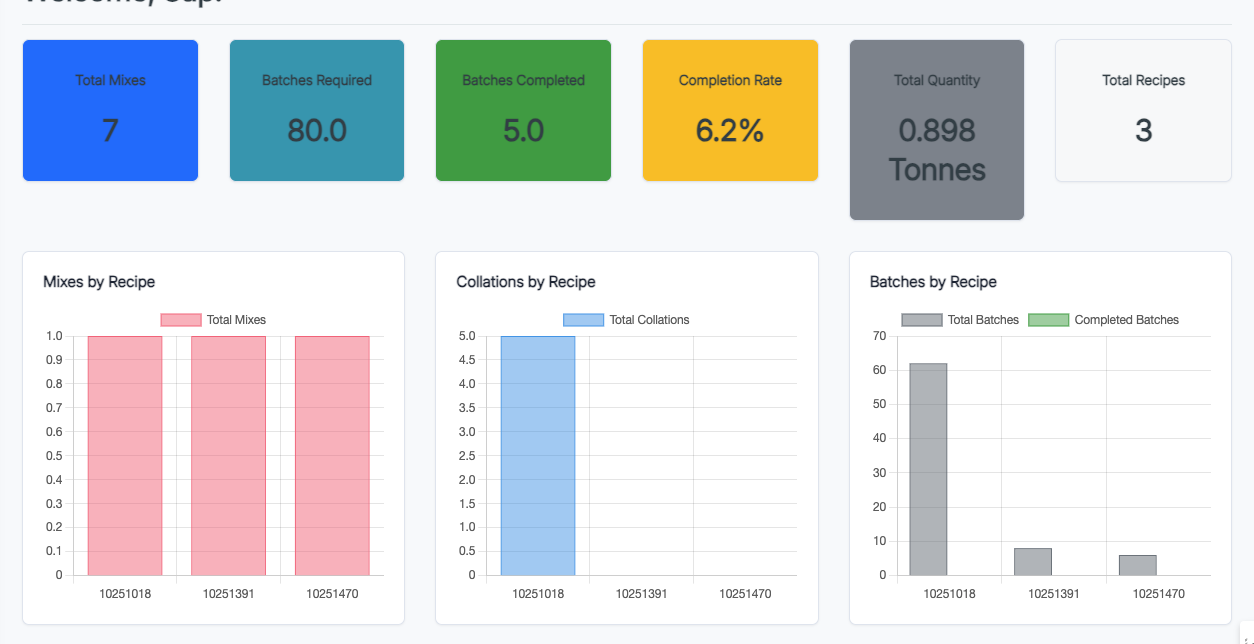

Achieve total accuracy and consistency in every batch with the TraceSense Recipe Weighing and Formulation Control System. Designed for food and manufacturing environments, our solution ensures every ingredient is measured precisely, traced completely, and recorded digitally—eliminating costly giveaways and out-of-specification batches.

With enforced tolerances, real-time feedback, and live data capture, TraceSense gives you complete control over your recipe formulation process while supporting full BRC and audit compliance.

Precision Weighing and Batch Control

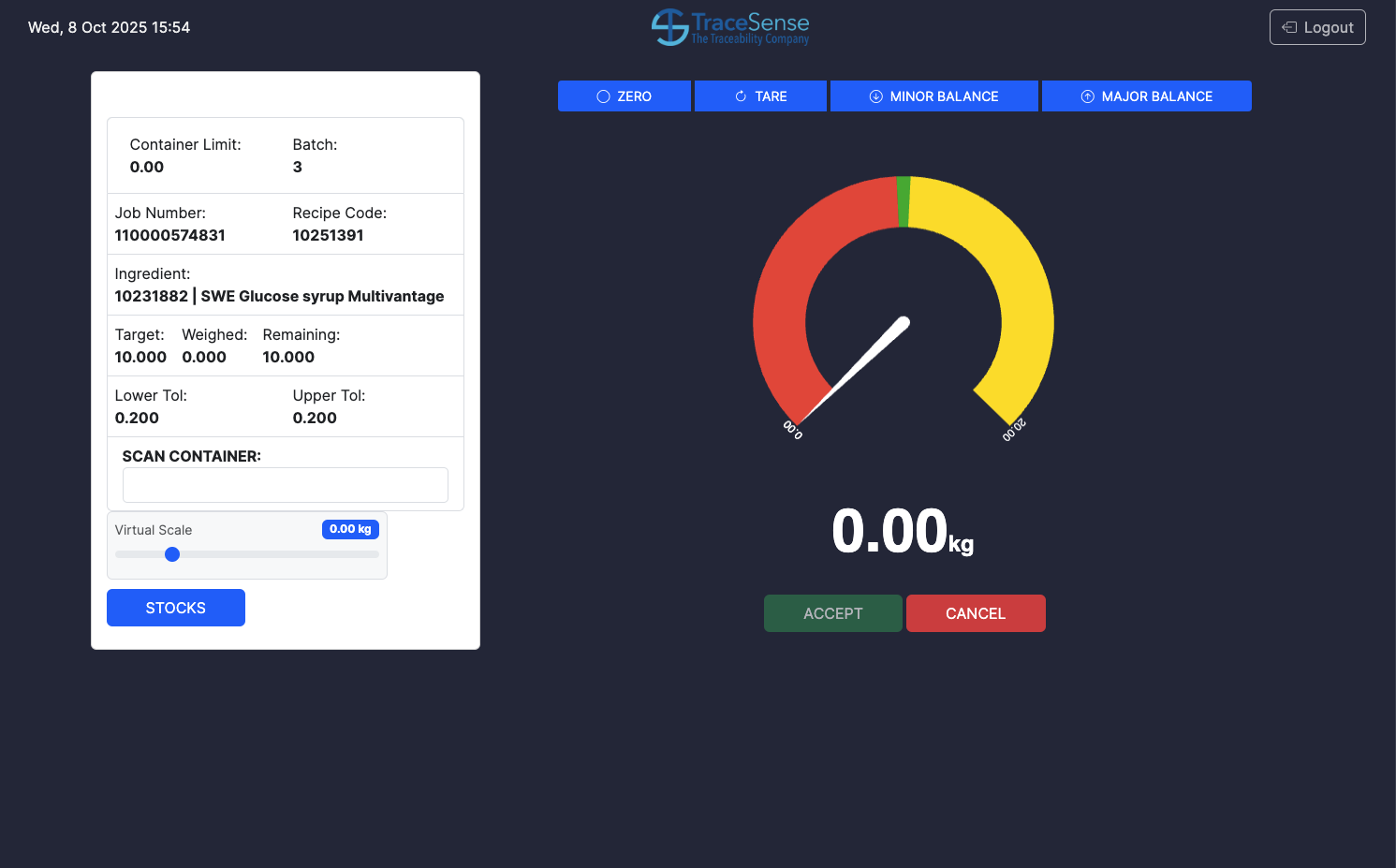

The TraceSense system enforces individual ingredient tolerances with a visual green speedometer-style indicator, preventing operators from proceeding until all ingredients are accurately weighed.

This step-by-step control ensures consistent batch quality, full traceability, and reduced material waste.

The system can connect to almost any modern industrial scale and is compatible with TraceSense TM2 Rugged Stainless Steel Panel PCs or portable tablets—allowing operators to weigh anywhere on the production floor.

Key Features of Recipe Formulation Management

- Step by step guidance through the recipe process

- Live accurate data recording

- Recipe instructions & H&S instructions / guides

- Ease of use, operator friendly

- Minimises wasted material

- Accurate live stock data

- Eliminates time-consumption paperwork

- Can integrate alongside our other modules to truly give you an end to end site

Ready to simplify and standardize your recipe weighing process?

Contact TraceSense today to schedule a demo and see how our digital formulation control system can transform your production accuracy.