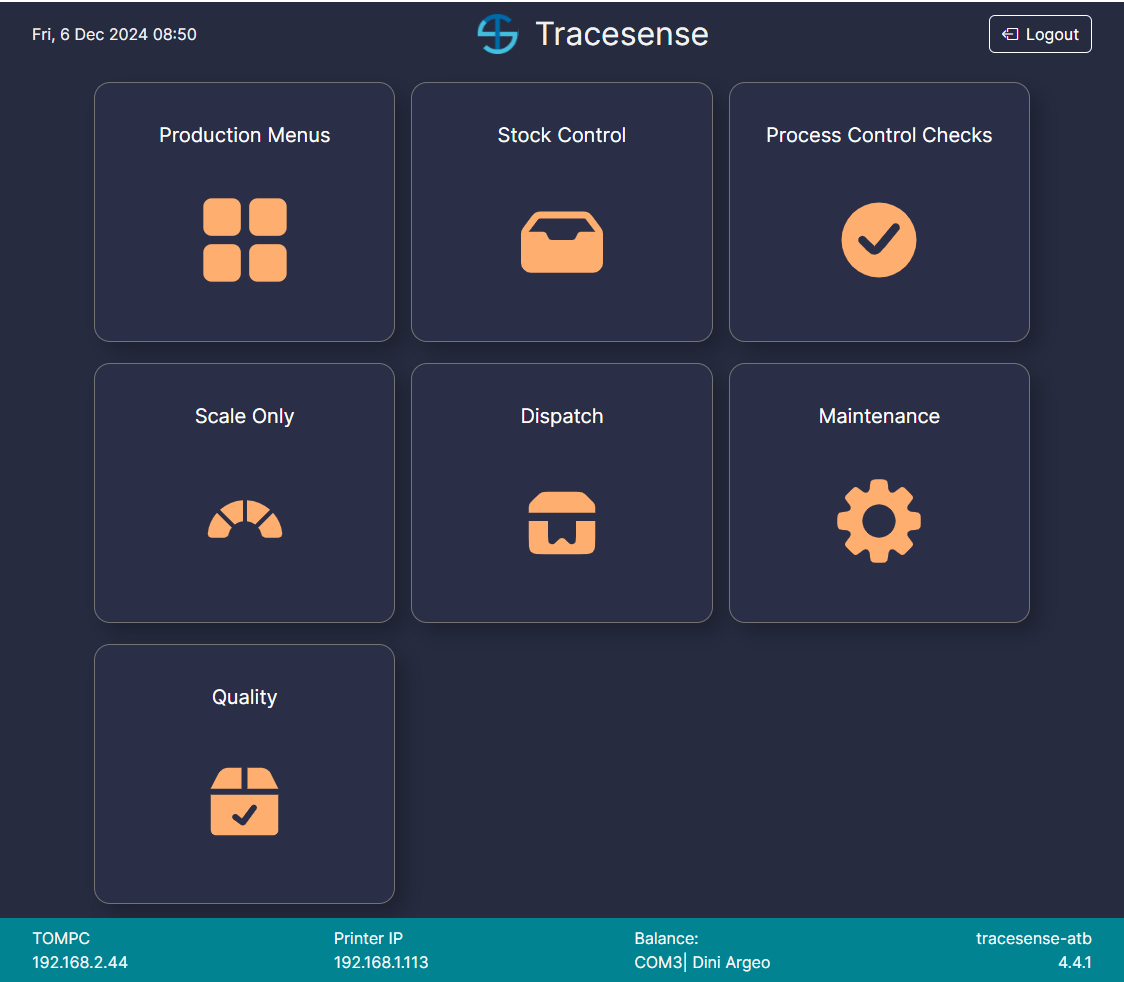

The TraceSense Food & Drink Traceability Software provides a complete, paperless solution for managing every stage of production—from ingredient weighing to end-of-line recording.

With a user-friendly dashboard and operator terminals, the system simplifies reporting, data setup, and daily compliance checks.

Real-time alerts notify your team of incorrect codes or incidents as they happen, while automated logs ensure full visibility and accountability.

Stay compliant, reduce paperwork, and improve efficiency across your entire operation.

Product Start Up Checks

Perform start-up checks effortlessly using a tablet or workstation. Capture images of non-conformances, verify product codes, and store photographic evidence directly in the system. Every step is recorded digitally—making audits faster, more accurate, and fully traceable.

Key Benefits:

- Complete product start-up checks on tablets or terminals

- Attach images, notes, and corrective actions instantly

- Ensure accurate code verification and reduce errors

Batch Control & Recipe Weighing

Connect TraceSense to your production scales for accurate recipe weigh-down and batch consistency.

Each ingredient is measured within defined tolerances and verified visually through the system’s green speedometer target zone.

Once all ingredients are confirmed, batches are automatically collated and ready for the next stage of production—helping eliminate giveaway, waste, and out-of-spec batches.

Features Include:

Seamless transition between batch stages

Real-time weighing accuracy and enforced tolerances

Full traceability of all ingredients and components

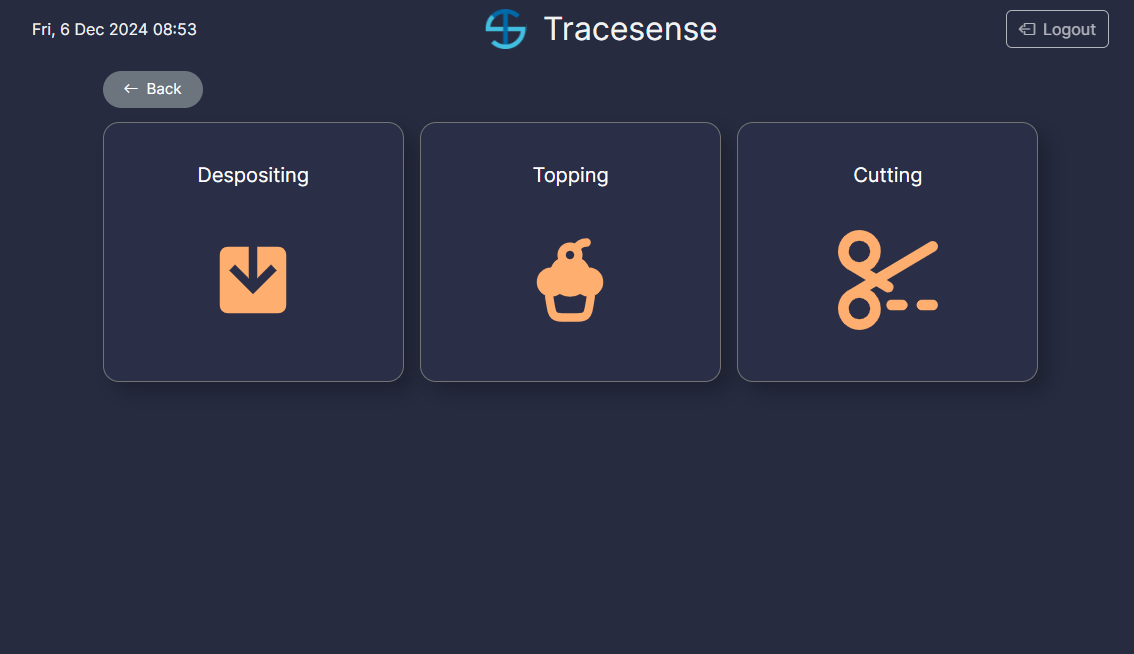

Rack N Track

Rack N Track allows you to record products produced against collated batches. The system allows you to ensure racks are used in rotation and you have full visibility of where the product goes.

You can record deposited racks, toppings on products and cutting.

Print Rack Tag Labels and ensure your racks are packed in the correct rotation.

Line Checks

Complete your Line Checks, Temperature Checks and if applicable Filler checks using our system.

Capture packaging components used and display photo standards to your staff. You can also display product specifications to easily in the system for reference also.

End Of Line Recording

Record finished good quantities for dispatch, capture packaging used at the line using the iPad device camera and mark items for export and rework.

Ready to transform your traceability process?

Contact TraceSense today to see how our Food & Drink Traceability Software can help your business stay compliant, efficient, and completely paperless.